HEX ENGINEERING

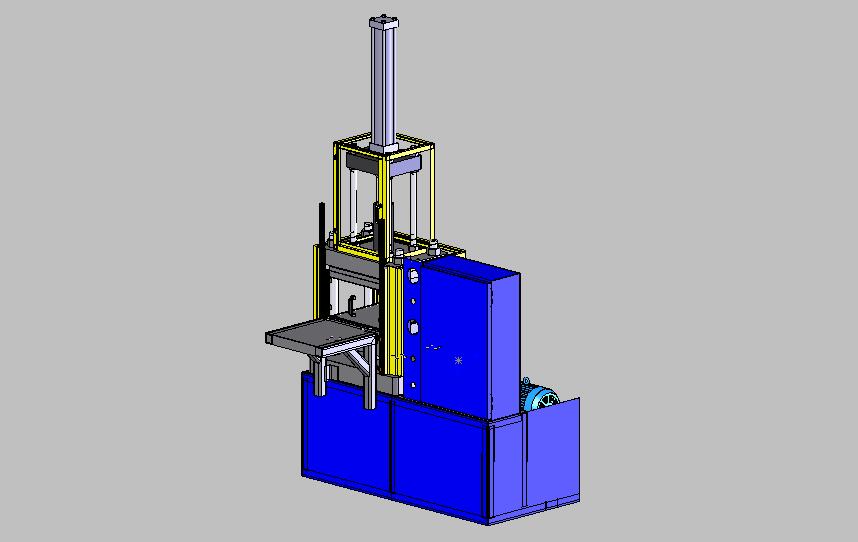

Case study 1: 50 ton hydraulic press

Client was in need for a 50 ton hydrualic transfer press for the manufacture of a rubber product. The transfer cylinder was needed to transfer the hot rubber into the rubber mold at a force of 15 tons. The mold is then pressed by the bottom cylinder to the required 50 tons. The completed machine was designed, analyzed, and project managed by Hex Engineering.

All of the moving platens, upper and lower bolsters, and four posts were sized using stress analysis and strength of materials-with an all steel construction. The hydraulic cylinders were sized for speed and required tonnage. The hyduralic pump was sized for the required flow, and the appropriate valve control system was designed. In addition, the electrical controls was designed-with an Allen-Bradley PLC used for the control logic.

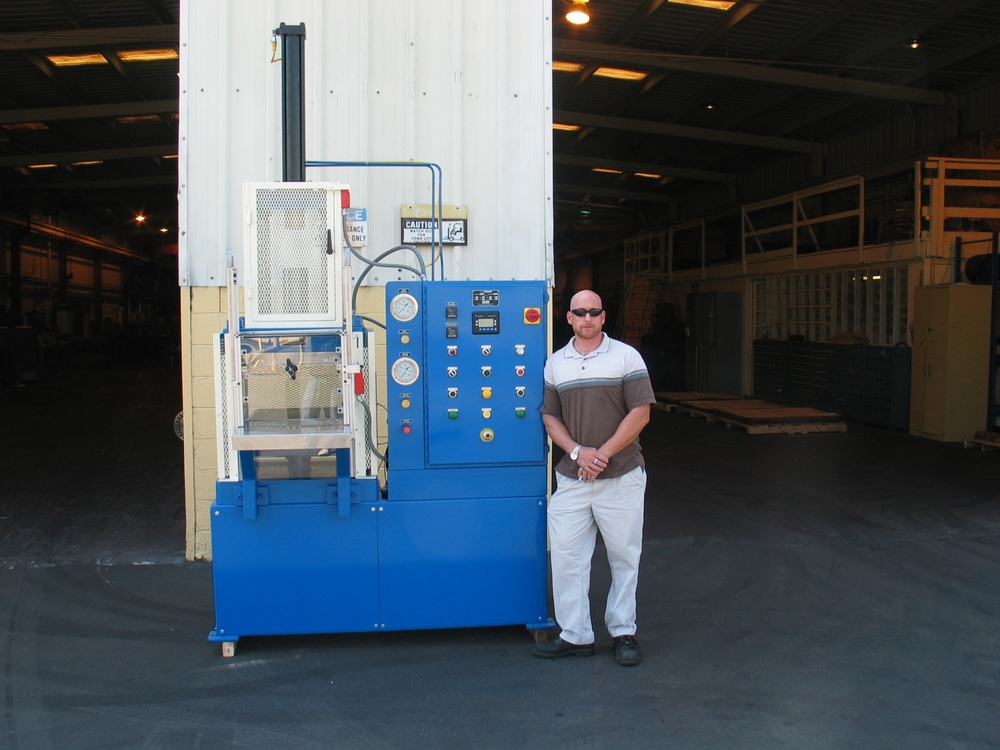

Manufacture and assembly of the final machine was sent out to a local manufacture due to the size of the components-with Hex Engineering managing the project through this stage. Final assembly and testing was then accomplished-then the part was shipped to the client with complete client satisfaction.

Below are pictures of the solid model and the final machine-with the owner of Hex Engineering in the picutre.