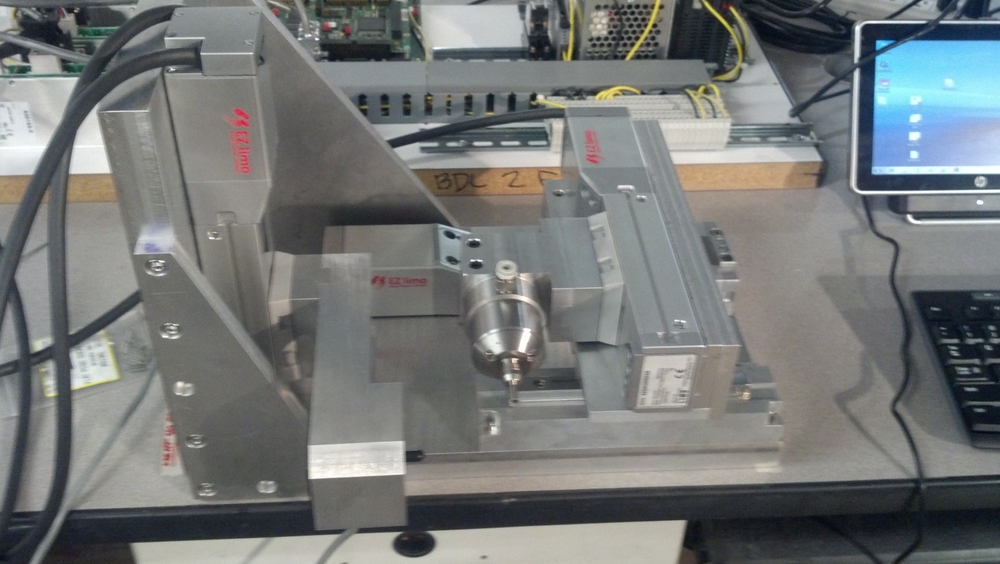

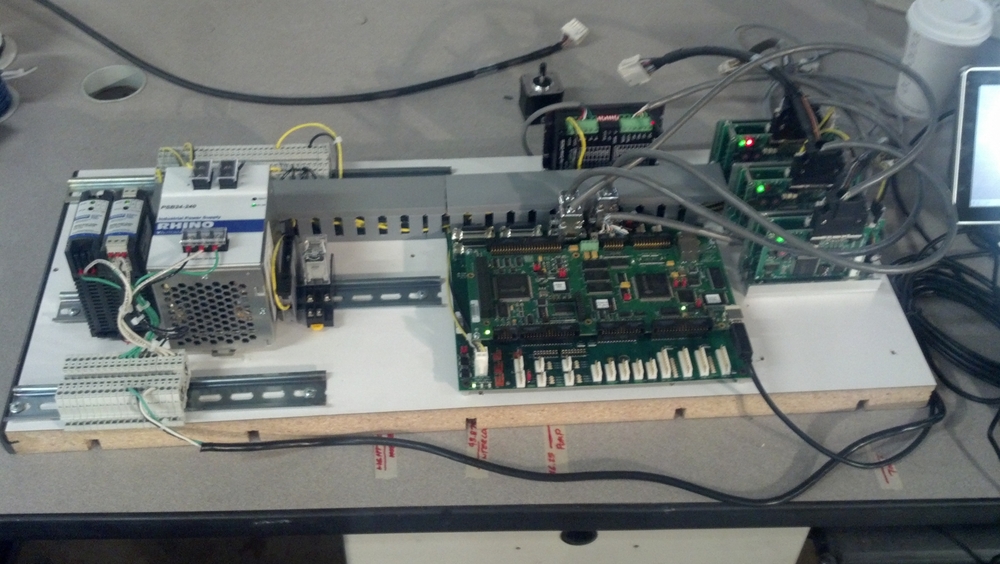

Case study 1: 4 axis milling machine

Client was in need for a 4 axis small milling machine for the medical device industry. Machine needed to be integrated into their existing housing, needed to lower the costs from their existing machine, and had to perform at least 2g acceleration profiles. Our solution was to use stepper motor driven linear actuators which were very cost effective. We utilized the actuators drives and for the motion control we used Delta Tau's Turbo Clipper Board.

After the mechanical design was done and approved, we had the parts machined and proceeded with the assembly. Due to designing for assembly, the prototype was assembled in about 4 hours-a reduction of days compared with the previous model. Electrical fabrication of the protoype took about 4 hours as well-with the programming integration with the controller took about 2 days.

We tested the machine with the client's product for a couple of weeks, which was very successful. Client was happy and the project was an overalll success. Below are some pictures of the prototype being assembled and the finshed product.